What is Quartz Crystal Microbalance

Quartz crystal microbalance (QCM) with dissipation measurement (QCMD) is a sensing technique that relies on measuring resonance properties (resonance frequency and quality factor) of piezoelectric resonators, or sensors. Usually, QCM sensors are made of quartz, hence the popular name of the technique. The resonance properties of piezoelectric resonators depend on their mass and their environment (exposure to air or liquid, temperature, etc). QCM measurements can therefore be used to measure minute changes in sensor mass, arising, for example, from the deposition of a thin film on the surface of the sensor, as well as other properties of such films (e.g., viscoelasticity), or to monitor the properties of the environment of the sensor (liquid or gas).

Operating Principle

A QCM sensor consists of a thin piece of quartz confined between a pair of metal electrodes. An alternating current applied to the quartz crystal induces mechanical oscillations in the quartz due to the piezoelectric effect. A wave is generated and that propagates between the opposite planes of the sensor and the films attached to it.

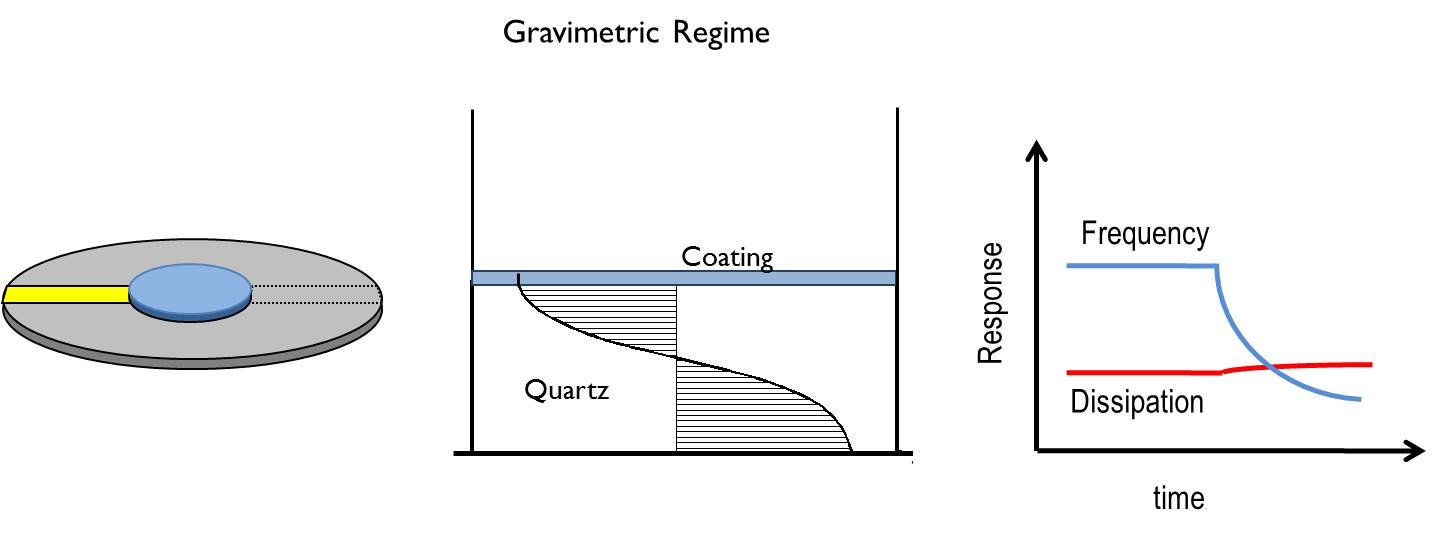

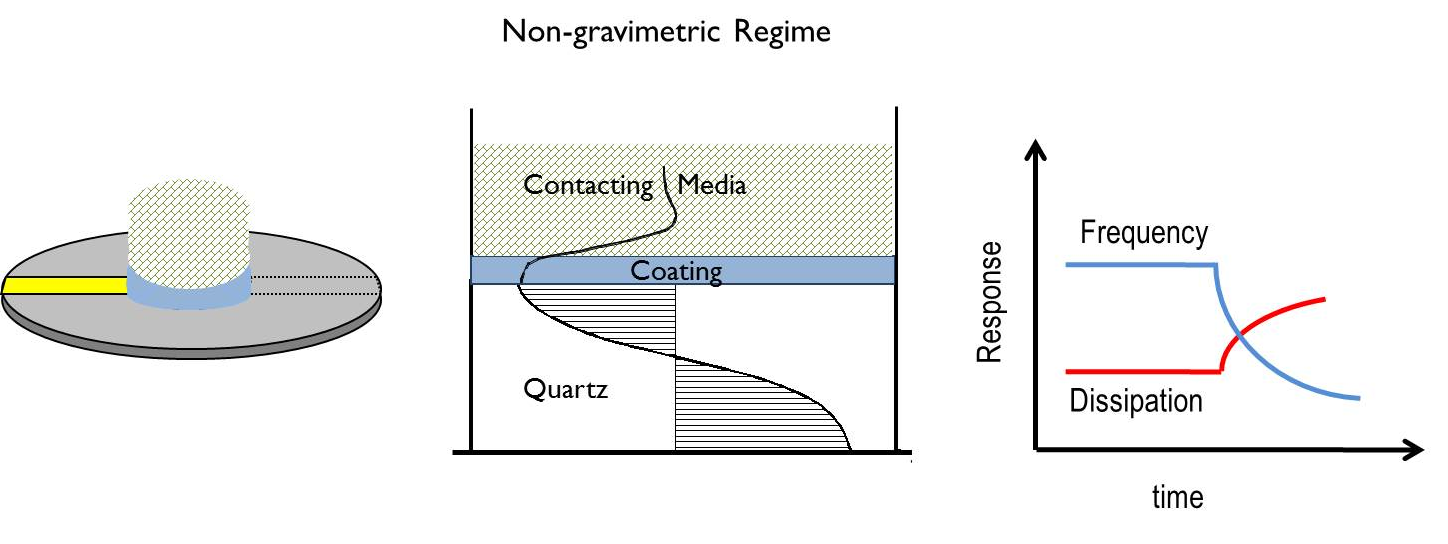

The resonance frequency of this wave depends on the oscillating mass of the sensor and its adhering layers. When a thin film is attached to the sensor, the properties of the wave change as well, modifiying the resonance frequency and amplitude. If the film is thin and rigid, the decrease in frequency is proportional to the mass of the film. In this way, the QCM works in the so-called gravimetric regime and the mass of the film can be calculated using the well-known Sauerbrey equation. If the film is not rigid, the measurement of the damped resonance enables the measurement of the viscoelastic changes of the film, allowing the characterization of the QCM working in the non-gravimetric regime.

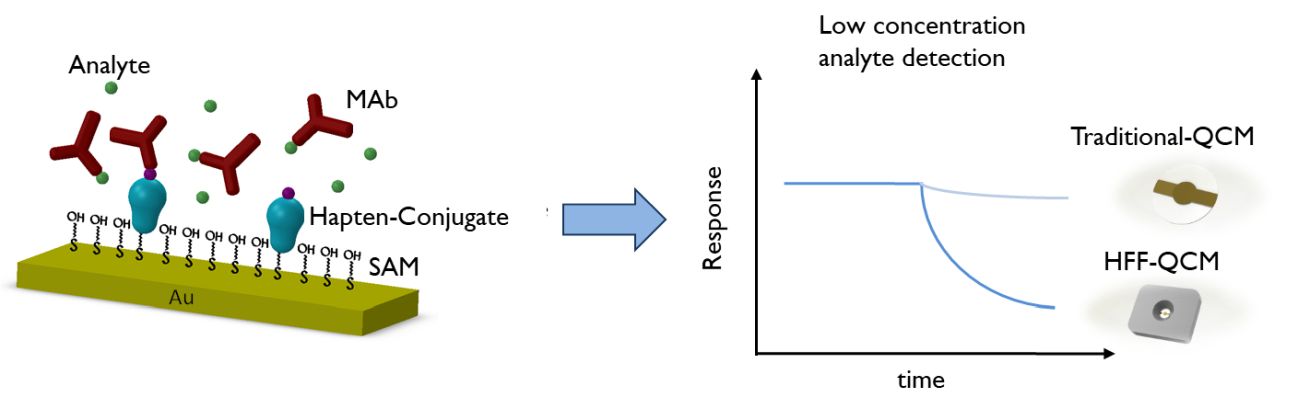

HFF-QCM (high fundamental frequency) sensors have a higher sensitivity than the classical sensors because the sensitivity depends on the resonance frequency. The improvement is ~ two orders of magnitude. Since the sensing area of the electrode is also reduced, HFF-QCM operates with much smaller sample volumes. AWsensors is unique in supplying commercial HFF QCM sensors and appropriate accessories for their use in measurement instruments.

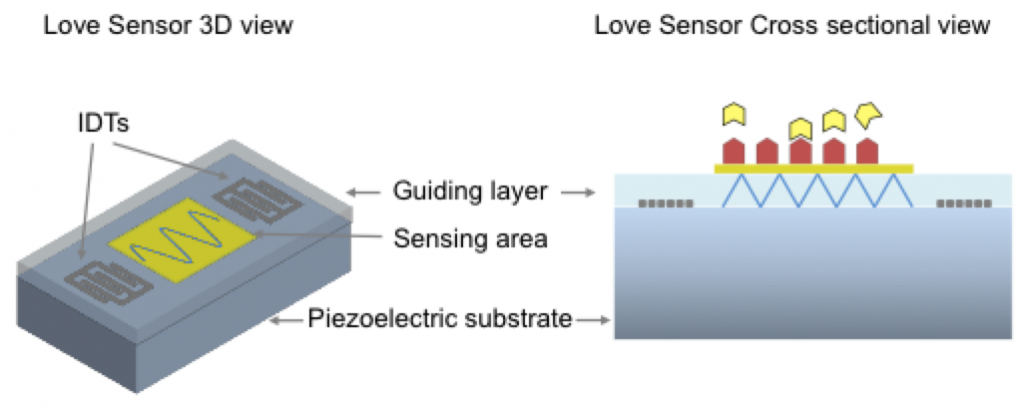

LOVE-SAW sensors consist of a thicker quartz piezoelectric substrate with an interdigitated transducer (IDT) on one end of the surface of the substrate, acting as signal input, and a second one, on the other end of the surface substrate, acting as the output. An alternating current applied to the input transducer generates a mechanical wave which propagates along the sensor device, from the input port to the output port. The wave travels confined in a guiding layer of a few microns height at the top part of the surface. When the properties of a film attached to the surface change (due to changes of mass, conformation, analyte binding, etc…), the propagation properties of the acoustic wave travelling along the sensor change as-well. The precise detection of the changes in those properties enables the characterization of mass and structural changes in the vicinity of the sensor surface with high sensitivity and resolution.

Recommended References on Quartz Crystal Resonators or Quartz Crystal Sensors

- Advanced electronic interface for the monitoring of AT Cut Quartz Crystal Resonators used as Acoustic Sensors in Fluid Media.

- Interface circuit for characterization Quartz Crystal Resonators based on parallel capacitance compensation

- A different point of view on the sensitivity of quartz crystal microbalance sensors