Ayuda InnovaTEIC 2020 IVACE concedida

06/08/2021. Advanced Wave Sensors S.L. (AWSensors) ha sido seleccionada como beneficiaria de una ayuda concedida por el Instituto Valenciano de Competitividad Empresarial (IVACE) para llevar a cabo el proyecto “Diseño, desarrollo e industrialización de un instrumento QCM-D de alta resolución multicanal” en el marco del programa InnovaTEIC 2020. Este programa ha sido financiado parcialmente por el Fondo Europeo de Desarrollo Regional (FEDER) dentro del Programa Operativo FEDER de la Comunitat Valenciana 2014-2020 cuyo objetivo es mejorar la competitividad de las PYMES valencianas.

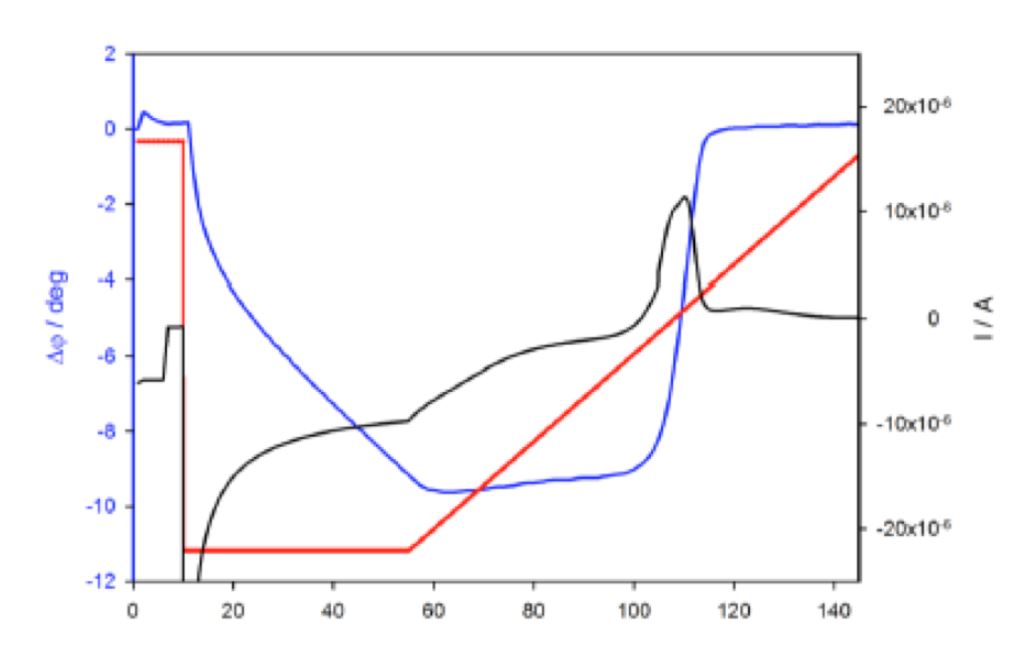

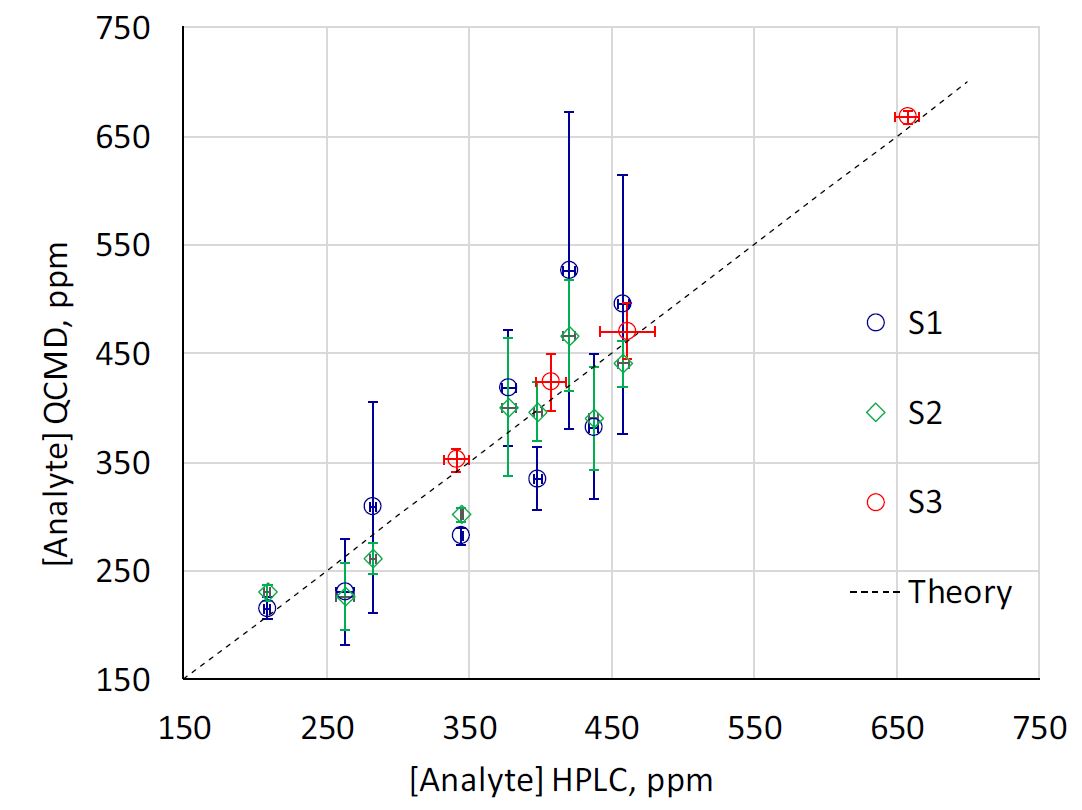

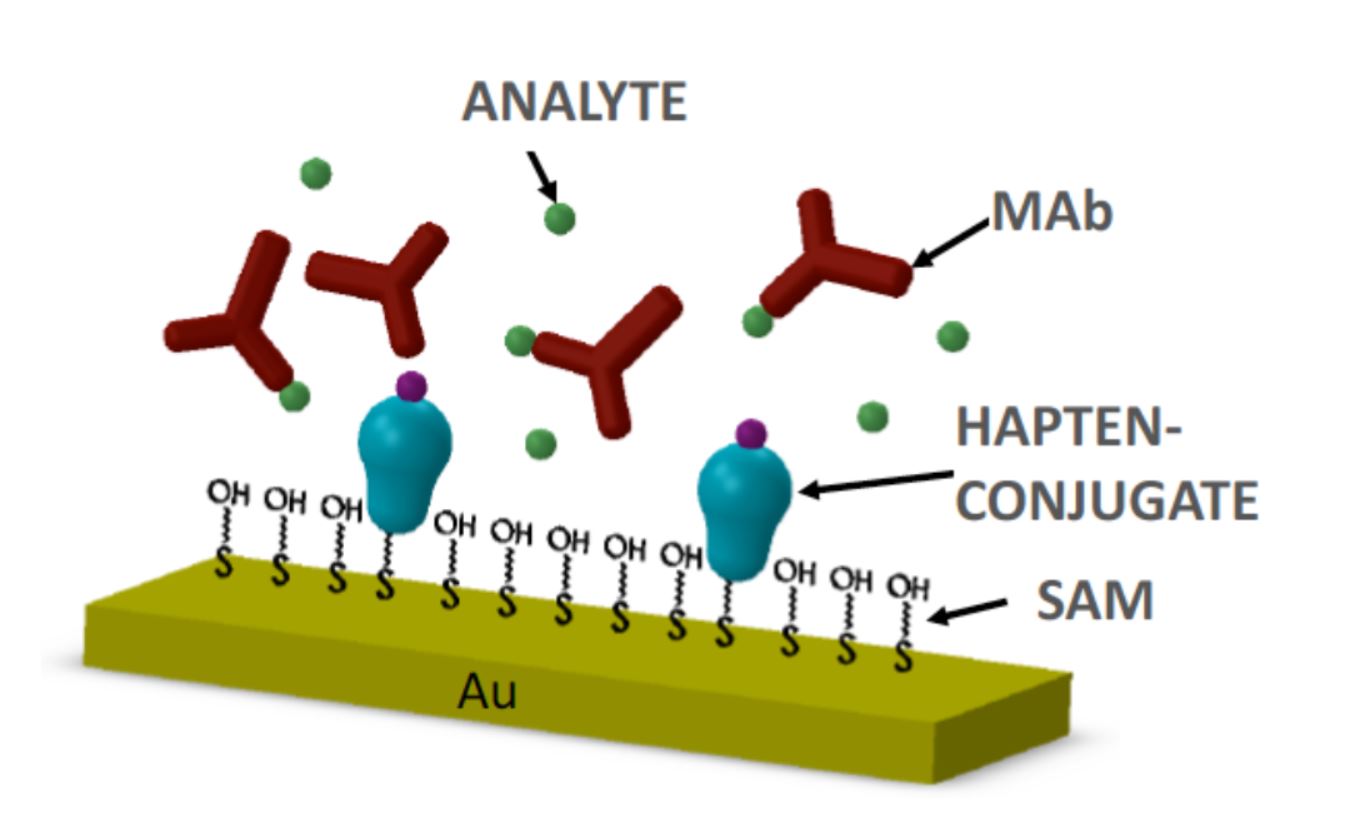

La presente actuación ha servido para desarrollar un nuevo instrumento científico, denominado X4, para la caracterización de sensores acústicos basado en una técnica protegida por la patente internacional PCT/ES2010/070409 en explotación actualmente por AWSensors. La plataforma X4 es capaz de caracterizar diferentes tipos de sensores micro/nanogravimétricos: QCM-D, HFF-QCM, SAW-LOVE, Torsional Wave,… que se emplean habitualmente en la detección y/o monitorización de interacciones biomoleculares como: reacciones antígeno-anticuerpo, detección de patógenos como bacterias y virus, adhesión celular, caracterización de la absorción de proteínas e interacciones DNA y RNA con secuencias complementarias. El rango de aplicaciones del citado instrumento es muy amplio y va desde la detección de patógenos en diagnóstico o seguridad alimentaria hasta la caracterización de las propiedades de nuevos nanomateriales.

Las principales innovaciones que presenta este dispositivo son: incremento en la velocidad de caracterización, paralelización de ensayos con la posibilidad caracterizar hasta 4 sensores simultáneamente, reducción de peso y tamaño para un instrumento semi-portable, mejora de la estabilidad térmica, mejora del diseño e inclusión de herramientas de post-procesado en software.