Cobalt EQCM Application Note

July 2nd 2021: AWSensors is pleased to invite you to take a look to its Cobalt EQCM Application Note entitled “Cobalt Deposition and Dissolution“.

Summary of the Note

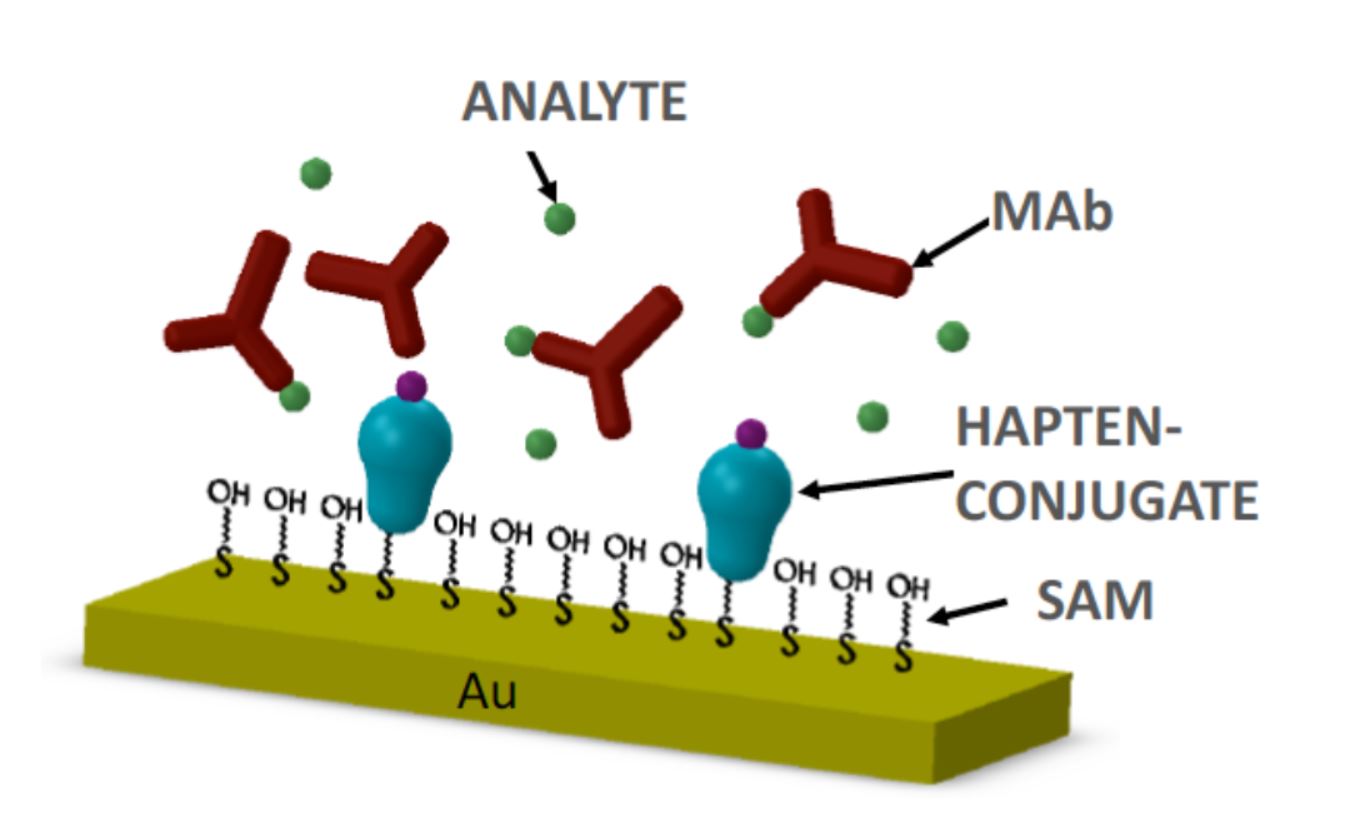

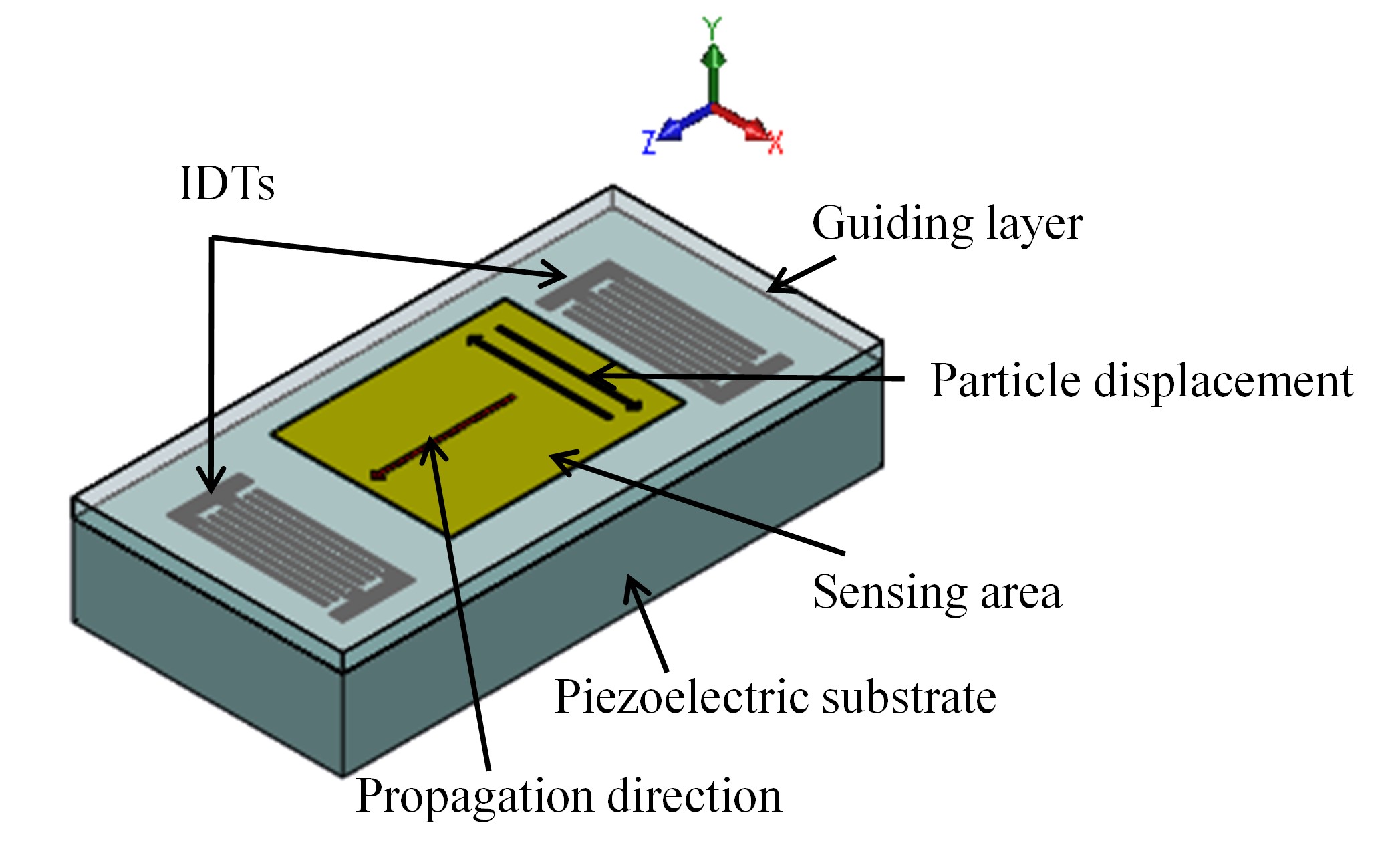

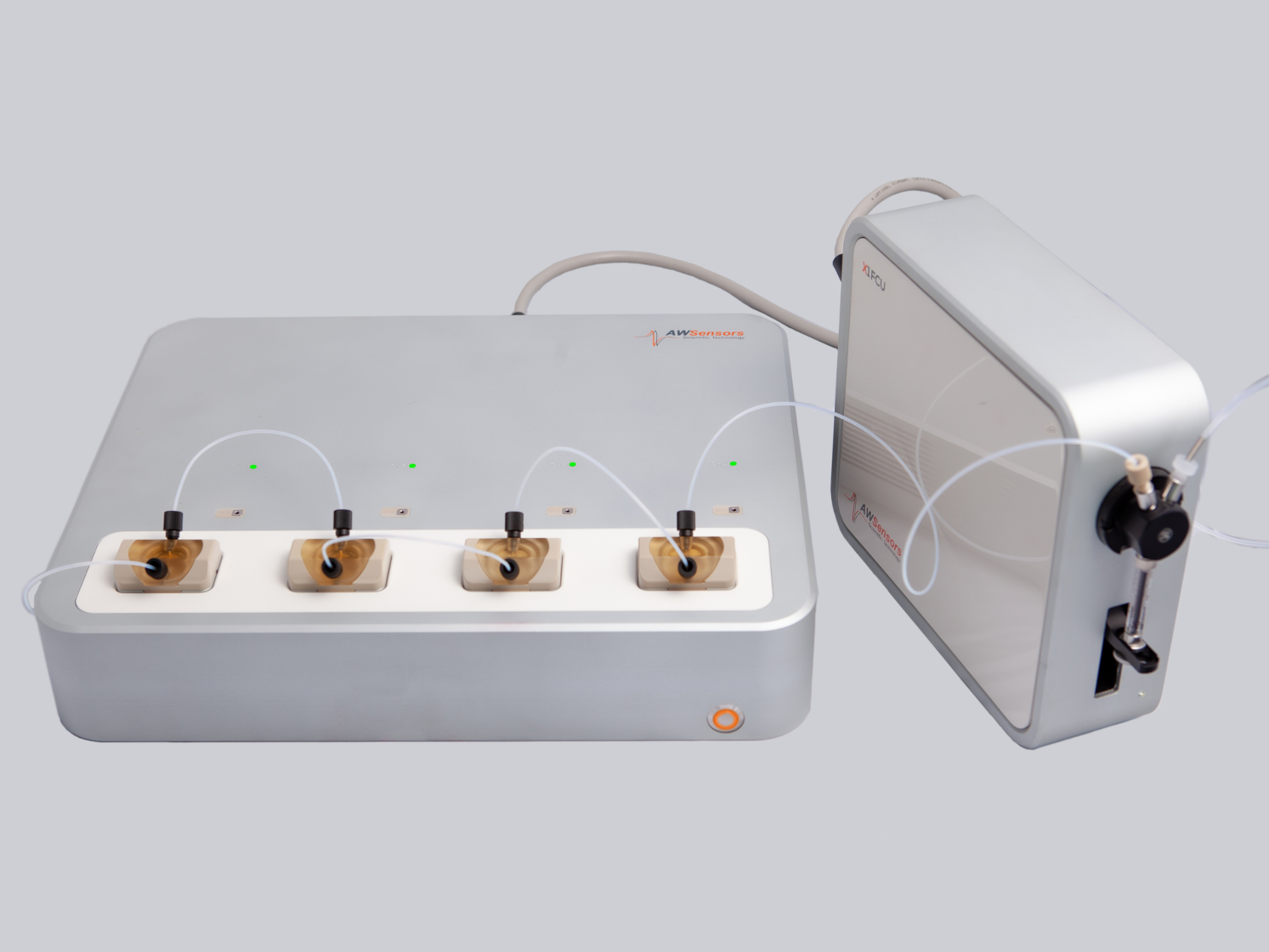

Use of AWS A20 RP in combination with a compatible potentiostat to perform an electrochemical study of deposition and dissolution of metallic layers onto the gold electrode of an AWS HFF-QCM sensor.

Materials and Methods

Materials:

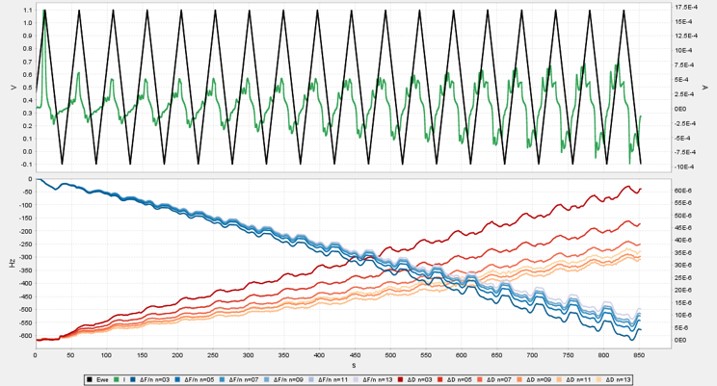

A 100MHz AWS HFF-QCM sensor was used with AWS A20 RP platform in combination with the SP-200 floating mode Potentiostat/Galvanostat from Biologic. The signals associated with the sensor phase monitoring in the AWS A20RP and the current and potential measurement of the SP-200 were monitored. The deposition solution was 10mM K2SO4 + 0.001M KCl + 0.001M H2SO4 + 0.001M (CoSO4)·7H2O solution. A Pt counter electrode was used with a saturated KCl solution Ag/AgCl reference electrode. The working electrode was the grounded electrode of the AWS HFF-QCM sensor.

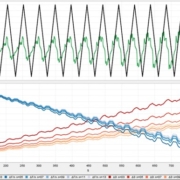

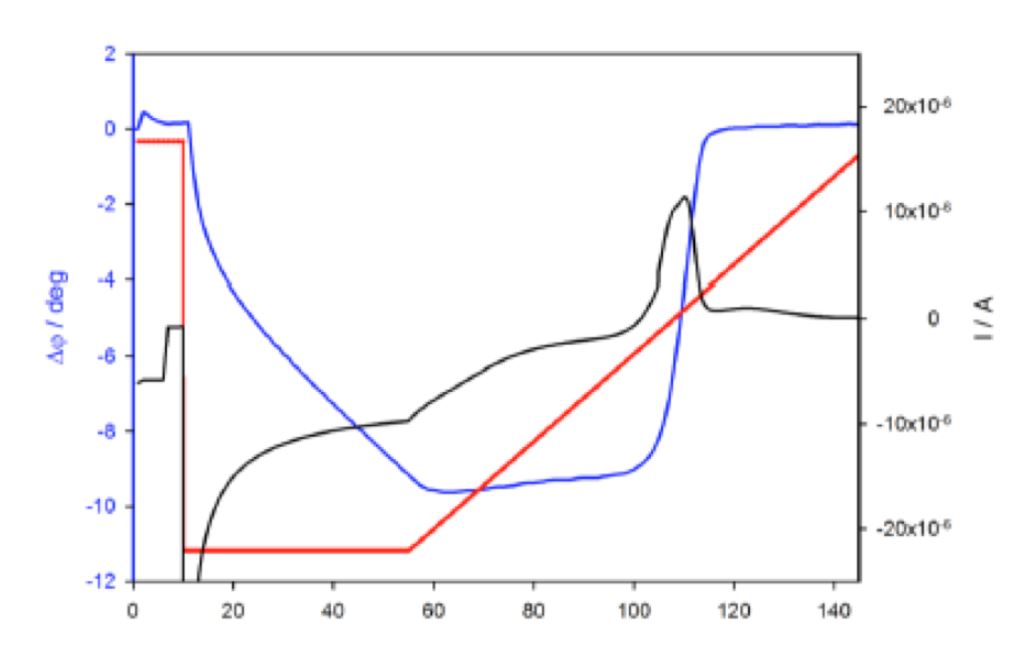

Cyclic Voltametry:

Determination of the Nernst equilibrium potential and the investigation of the overpotential deposition of Cobalt on the gold electrode of the HFFQCM. The potential was held at –0.4V ten seconds before starting the cyclic voltammetry. A potential scan with a rate of 10mV/s was applied from –0.4 to –1.5V.

Underpotential Deposition:

Controlled deposition of atomic layers of Cobalt on the AWS HFF-QCM sensor.

Download Full Application Note

You can download the full Application Note in pdf file from this link or download it from our Applications Web Page where you can find this and the rest of our Application Notes.